Fill in the form below to order a kit today

Smallholders are often neglected by innovators who favour building large centralised bespoke units that maximise economies of scale. We see the masses of UK Smallholders as a vital part of the low carbon food production economy and as such we have developed our tray-based options. This can be scaled to the needs of the unit or up graded to a Bio Conversion Unit or HVAC Warm Room. We want to create a community of Smallholders with poultry so that together we have a significant impact on valorisation of organic waste and the reduction of carbon associated with eggs and poultry.

Our offer to Re Gen Farmers starts with a simple tray to try out bioconversion to understand which of their organic wastes work best and how their hens respond to being fed Black soldier Fly Larvae. The next step is to use one of our Bio Conversion Units which can be quickly and simply rolled into place to start production. This may then be followed by a HVAC warm room which is a temperature controlled and ventilated room where Black soldier Fly Larvae can be raised. We design, commission and support this facility so that it is cost effectively operated and fully productive.

We work with Doug Wanstall at Bank farm in Kent because he is a progressive Regenerative (Re Gen) farmer with a can-do attitude. We are building an integrated demonstration unit to showcase how several processes integrate within the farm. ReGenBen in Hereford is likewise progressive and can-do and here we are testing our Black soldier Fly Larvae for his hens.

Poultry Farmers

With the global poultry industry producing 360 million tonnes of greenhouse gas emissions every year, zero-emission farms are an urgent necessity.

Sustainable farming solutions such as onsite or local food waste management to reduce soya from your feathered friend’s diet will start you on the right path to becoming a carbon-neutral farm.

Consumers are demanding more sustainable products and are willing to pay more for the pleasure. Having a farm revolved around carbon neutrality will make you more visible and valuable to high-street retailers looking to delight their customers.

Fruit and veg Farmers

The fresh produce supply chain produces 170,000 tonnes of food waste every year. Most food waste ends up in landfill or is incinerated which heavily contributes to global warming as food releases methane gas as it decomposes. Food waste is full of water, making it heavy and costly to transport. By implementing an onsite Bio Conversion Unit or sending your excess food to a locally managed unit, you can save time, money and reduce your carbon footprint. Just 1 large Inspro Bio Conversion Unit can devour 500 tonnes of food waste in 1 year – that’s heavier than 3 small houses!

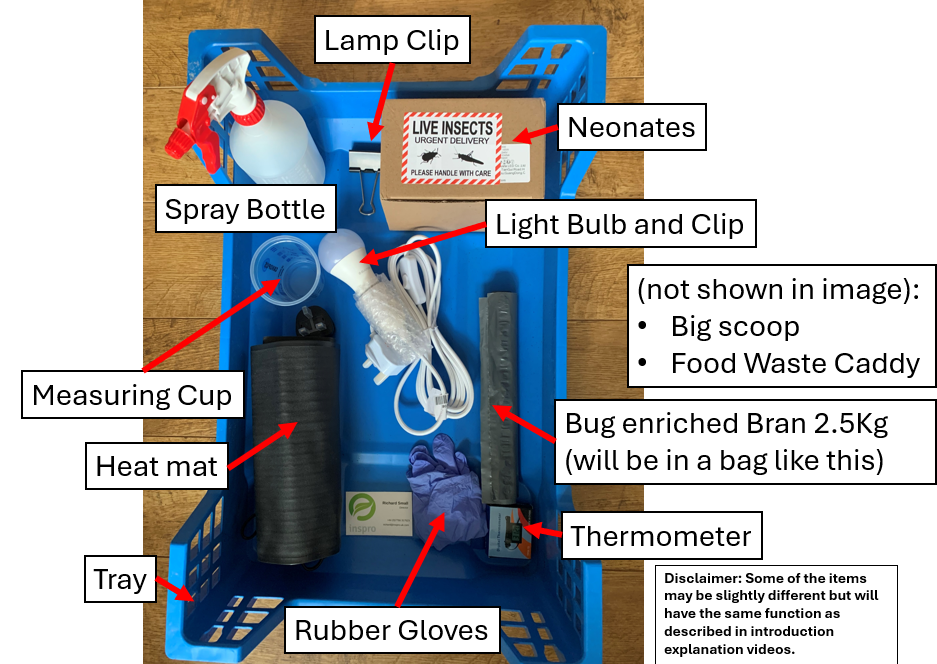

Smallholder Starter Box contents:

kit Price (UK Delivery and your first 50K Neonate bottle included)= £105

Bottles will last approximately one month (dependant on your demand/ number of chickens)- re-order your bottles directly via Email- richard@inspro-uk.com or through Smallholders WhatsApp Group Chat Please.

Full Instruction Included and Online Support available (Contact us)

Complete the form below to purchase a ‘Live and Local’ kit today (Invoice will be sent via email)